nofima.no

Creating value

2013

9

Financed by:

The Research Council

of Norway

Partners:

SINTEF ICT and

SINTEF Fisheries and

Aquaculture

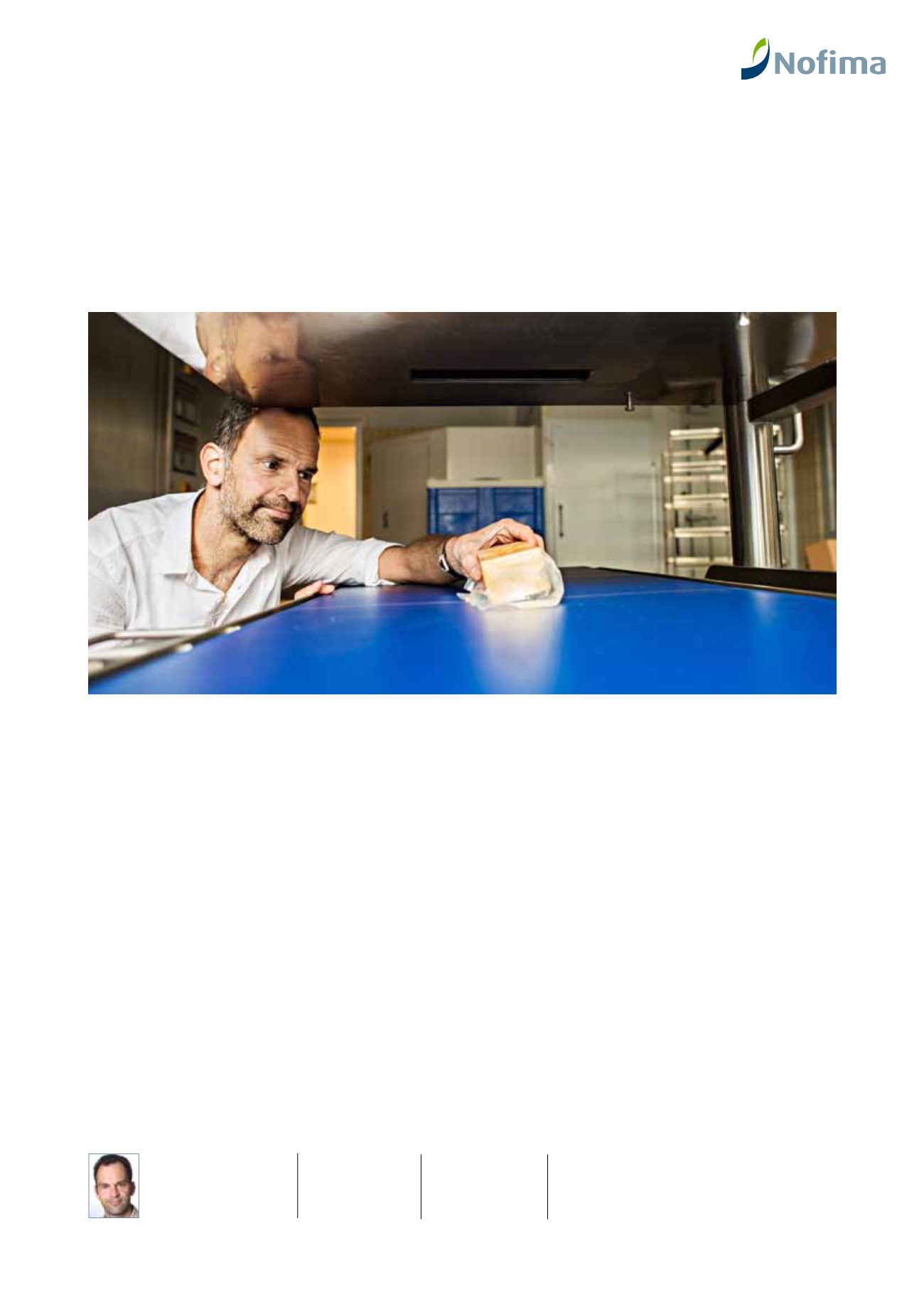

Nofima Senior Research Scientist Jens Petter Wold scans a block of cheese in an NIR scanner in the laboratory.

photo: Jon-Are Berg-Jacobsen © nofima

Novel sensors and automation is the name of a project

in which the main objective is to develop sensor technol-

ogy that can help food companies to optimize utilisation

of raw materials, improve logistics, increase profitability

and minimize wastage.

The research in this project is divided into two parts:

1. Further development of existing sensor technology in

order to exploit what researchers have already made in

the best possible manner.

2. Development of completely new sensor technology,

small and cheap sensors, so the food industry (and other

industries) to a greater extent can make use of this tech-

nology in order to become more hi-tech and automati-

cally quality controlled.

“In the long term this will strengthen competitiveness

and safeguard market channels,” says Nofima Senior

Research Scientist and Project Manager, Jens Petter

Wold.

Precise measurements:

One example from the project

is the development of a system to automatically sort fish

by species, size and exterior qualities.

“We are using a camera and a laser line that scans

the fish and provides feedback to a computer about how

much the fish weighs, exterior quality and which species

it is,” says Wold.

Such a system provides opportunities for far more

precise and detailed sorting than is the case with the

current system, and consequently better utilisation of

the raw material.

Another example is the development of automated

and more precise measurements of fat and fat composi-

tion in, for instance, milk. This utilizes Fourier Transform

Infrared (FTIR) spectroscopy.

“This will give the producer detailed quality informa-

tion about the milk and the possibility of optimal use

during further processing,” concludes Wold.

Sensors adapted for use in the food industry make automatic and

precise sorting of raw materials possible, and improves efficiency.

Measure quality, save money